Equipment

Achieving customer satisfaction and driving increased exports depends on the implementation of rigorous quality control processes. To ensure that our products, including bathroom, kitchen, commercial faucet and accessories, plumbing fixtures, valves, faucets, garden parts, fittings, and industrial components, meet the highest global market standards, we ensure that each product undergoes thorough self-inspection throughout the manufacturing process. This includes adherence to strict protocols such as first article inspection, comprehensive testing, and continuous monitoring to maintain consistency and precision in production.

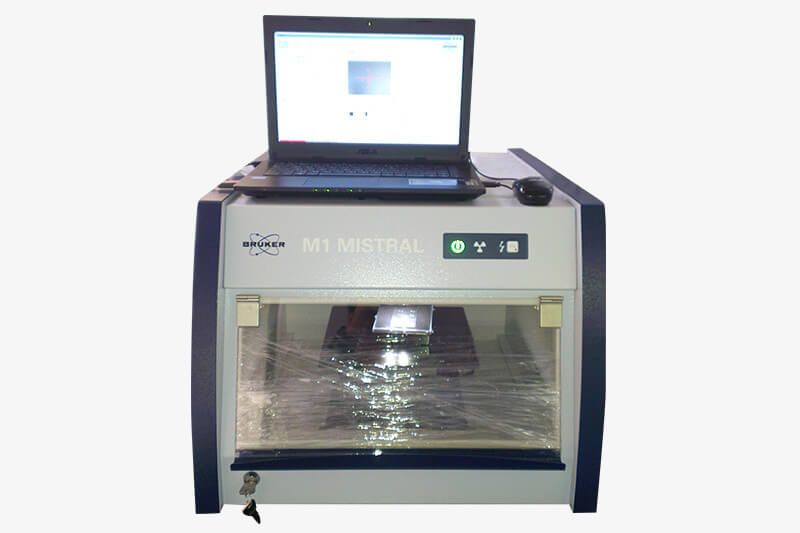

Our partners are equipped with up-to-date testing equipment, including salt spray chambers for corrosion resistance, endurance testing to evaluate long-term performance, film thickness measurements, drip, and leak tests to ensure product integrity, spectrometer analysis for material composition, destruction testing to verify durability under extreme conditions, and high-temperature ovens to assess heat resistance and stability. These investments in advanced testing facilities enable us to continuously develop defect-free products while offering a comprehensive range of services to meet the ever-changing needs of our customers. Through these efforts, we ensure that our products not only meet but exceed the expectations of clients across diverse markets.

Quality Testing Equipment

We employ a comprehensive range of top-tier testing instruments to ensure rigorous quality control, including:

Surface Characteristics Measurement

Advanced tools help us ensure each coating meets exact standards for texture, smoothness, and finish.

Environmental Simulation Testing

We test our coatings under simulated conditions—such as temperature changes, humidity, and corrosion—to ensure reliable performance and durability in real-world environments.

Physical Properties Measurement

We measure hardness, adhesion, and thickness to ensure our coatings meet the highest standards of strength, durability, and performance.

Optical Characteristics Measurement

We test gloss and other visual properties to ensure our coatings meet customer expectations and industry standards for optical performance.