OEM Parts

At BYSON, we employ a range of advanced precision manufacturing technologies tailored to meet the specific needs of each client. With extensive experience in OEM production, we are dedicated to delivering high-quality, reliable plumbing components and faucets that offer accuracy and durability across various industries.

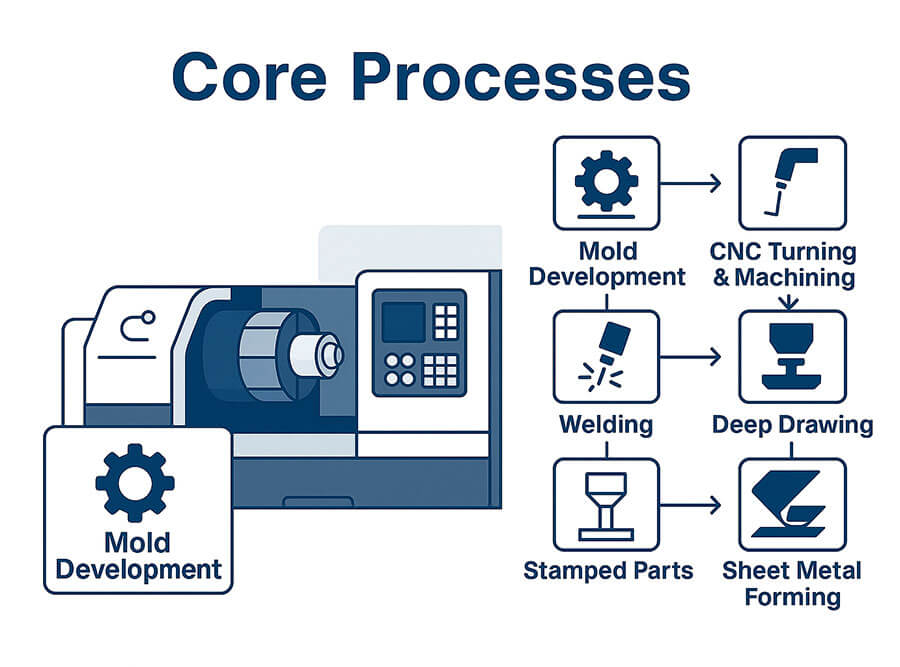

Core Processes

-

Mold Development

In-house mold design and production for injection molding and metal forming applications, ensuring precision and durability

-

CNC Turning & Machining

High-precision machining services including lathe turning, milling, and drilling for complex metal parts.

-

Welding

Skilled welding techniques to assemble components with strength and accuracy, including ultrasonic welding for plastics.

-

Stamped Parts

Precision stamping to create complex metal shapes with consistent quality and repeatability.

-

Deep Drawing

Advanced deep drawing processes to form metal sheets into intricate, high-strength parts.

-

Sheet Metal Forming

Custom sheet metal bending, folding, and forming to produce structural and aesthetic components.

Our OEM Process Includes:

-

Consultation & Design

Share your ideas or specifications – our team will help shape them into a manufacturable product.

-

Sampling & Prototyping

We provide professional sample development, ensuring every detail meets your expectations before mass production.

-

Costing & Quotation

Transparent pricing tailored to your project scale and technical requirements.

-

Production & Quality Control

All products go through rigorous quality checks at every stage of production.

-

Packaging & Custom Branding

From private labeling to customized packaging, we deliver solutions that enhance your brand identity.

-

Delivery & After-Sales Support

Reliable logistics and long-term support to ensure a smooth and lasting partnership.

Low MOQ & Pilot Runs

Flexible support for small orders and trial production to meet your unique project needs.

Pilot Runs

At Byson, we provide pilot run services to validate designs, materials, and production processes before full-scale manufacturing. This ensures optimal performance, minimizes risks, and allows timely adjustments for a smooth transition from prototype to mass production.

Low MOQ

We offer flexible low MOQ options to support small orders and customized projects, helping you reduce inventory risk and quickly respond to market demands.

From Concept to Production — Across All Materials

Material-Based Product Guide

At Byson, we offer complete OEM capabilities to design and manufacture products across a wide range of materials. Whether it’s stainless steel, plastic, zinc alloy, brass, steel, or aluminum, our in-depth expertise and advanced manufacturing know-how ensure high-quality, customized solutions that meet your specific requirements.

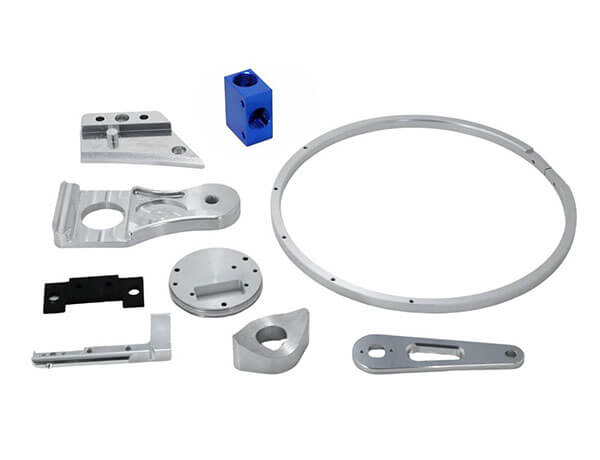

OEM Products

Plastic Parts

Stainless steel Parts

Steel Parts

Zinc alloy Parts

Aluminum Parts

Brass Parts

With years of experience and a skilled manufacturing team, we are committed to providing flexible, efficient, and dependable OEM services that help your brand stand out in the market.

Let’s build your product together – contact us today to get started.